Embarking on a Cool Journey: Your Quick Guide to RV AC Mastery

Sunbeams dance on the dash, a familiar rhythm accompanying your well-worn road trip playlist. The wind ruffles the curtains, carrying the scent of pines and seasoned adventures. Your RV hums along, a trusty steed guiding you deeper into the wild. But wait… that comforting drone falters, replaced by an ominous silence. The temperature creeps up, your sanctuary morphing into a familiar foe: the sauna-on-wheels. Fear not, seasoned and rookie campers alike! This guide is your trusty compass through the wilderness of AC woes, packed with tips and tricks for both veteran hacks and newbie heroes. Let’s reclaim your cool haven and keep the campfire stories simmering, not your fellow passengers.

For a comprehensive guide on maintaining your RV’s air conditioner, visit Camping World’s blog.

Mastering RV AC Basics: The Foundation for Cool Comfort

Imagine navigating sun-drenched landscapes, the breeze whispering through windows, your soundtrack painting the perfect road trip scene. Suddenly, a chill creeps in – your trusty AC, usually a silent guardian of comfort, has fallen silent. But fear not, intrepid adventurer! Building a cool haven on wheels starts with laying a solid foundation of RV AC basics.

1. Regular Maintenance: Your Comfort’s Secret Weapon

Think of your AC like a trusty steed – consistent care keeps it galloping happily. Skipping simple but crucial tasks like monthly filter cleaning is a common misstep. A clean filter isn’t just about preventing breakdowns; it’s the key to smooth airflow and a pleasantly cool interior. RV Lifestyle Magazine offers a treasure trove of filter maintenance tips, ready to empower you to become your AC’s best knight in shining armor.

2. Powering Up: Avoiding Mishaps at the Plug

Remember, your RV’s AC isn’t a houseguest who can share your coffee maker’s juice. RV and residential AC systems have different power appetites, and mixing them can lead to a zapping fiasco. Ensure your AC unit is hooked up to the right power source, like a trusty knight matching the voltage with his trusty steed. Camping World’s blog dives deep into the world of RV AC power supply, offering vital troubleshooting tips to keep your electrical adventures safe and smooth.

3. Leveling Up: The Unsung Hero of Cool Journeys

Uneven terrain isn’t just a bump in the road for your suspension; it can throw your AC’s efficiency into a tailspin. Correctly leveling your RV is like adjusting your knight’s saddle for optimal comfort. It ensures optimal air circulation throughout your haven, keeping you cool and collected no matter the campsite’s contours. This often-overlooked aspect is the secret weapon for unlocking your AC’s peak performance.

Remember, consistent care, the right power match, and a level playing field are the cornerstones of a cool and comfortable RV. With these basics mastered, you’ll be well on your way to conquering any AC hiccup and reclaiming your mobile oasis!

Unleashing the Inner Iceberg: Navigating Your RV’s Chill Zone

Your RV is your mobile oasis, and your trusty AC, the frosty guardian keeping it cool. But just like any adventurer needs to understand their terrain, mastering your RV’s “chill zone” requires navigating some unique challenges. Let’s dive into the secrets of preventing overheating, making smart power plays, and discovering hidden efficiency boosters.

1. Taming the Heat Monster: Avoiding Overheating and Unnecessary Repairs

Regular maintenance isn’t just a friendly suggestion; it’s a battle cry against the heat monster! Matching your AC’s needs to its power source is like equipping your knight with the right sword. An RV needing 30 amps of juice won’t magically become cooler by plugging into a measly 15-amp outlet. And those dual AC units in 50-amp fortresses? They crave the full 50-amp feast to keep your haven comfortably frosty. Overheating and unnecessary repairs are no match for an informed adventurer!

2. Power Plays and Shady Tactics: Boosting Efficiency Like a Pro

Understanding your RV’s AC power requirements isn’t just about avoiding electrical meltdowns; it’s about unleashing its chilling potential. Imagine your RV basking in the sun like a sun-kissed lizard. Parking it in a shaded area is like throwing a cooling cloak over its shoulders, instantly lessening the burden on your AC. It’s a simple power play that packs a frosty punch!

Remember, fellow adventurer, knowledge is your weapon against overheating and inefficiency. Embrace your RV’s unique “chill zone,” conquer the power puzzle, and bask in the comfort of your perfectly cooled haven, no matter where the road takes you!

DIY AC Mastery: From Zero to Hero on the Road

Ah, the open road beckons, sun glinting off your chrome fortress. But hold on – a chill breeze used to accompany that scene, right? Fear not, intrepid DIYer! This section equips you with the tools and know-how to transform yourself from AC amateur to troubleshooting hero, right there on the asphalt battlefield. For detailed guidance on RV air conditioner maintenance and troubleshooting, check out: Camper FAQs – RV Air Conditioner Repair and Troubleshooting Guide.

Safety First: Your Guiding Star in the Circuit Jungle

Remember, your AC’s well-being is your comfort’s compass. Simple tasks like monthly filter cleaning aren’t just chores; they’re pre-emptive strikes against the gremlins of overheating. Think of it as sharpening your trusty wrench, always ready to ensure smooth airflow and prevent potential foes.

Basic Diagnostic Checks: Your AC’s First Aid Kit

Before diving headfirst into the electrical labyrinth, let’s equip you with some essential tools. Our guide demystifies the “Fuse Frenzy,” showing you how to identify and replace those tiny power guardians with ease. No more tripping over “Breaker Bonanza” either! We’ll walk you through safe resetting and guide you towards addressing any underlying electrical whispers. And don’t forget, uneven terrain can throw your AC’s chill off-kilter. Learn how to “Level Up Your Game” and unlock optimal airflow, no matter how bumpy the campsite terrain.

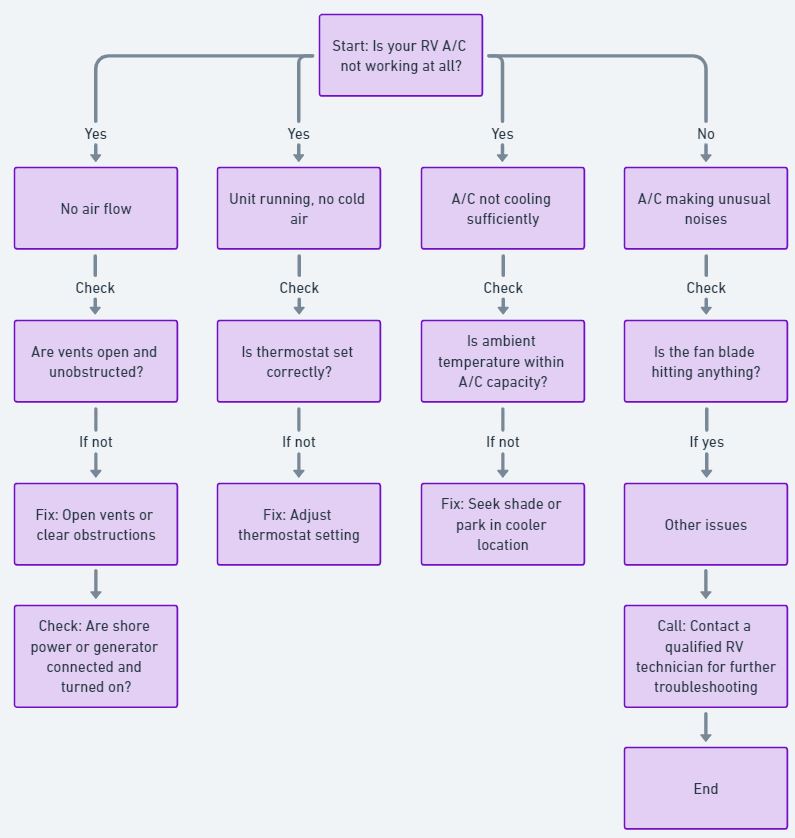

Interactive SOS: Your Troubleshooting Lighthouse in the Storm

Feeling lost in the fog of AC woes? No worries! Our user-friendly flowchart is your beacon in the storm. Answer a few simple questions, and voila! You’ll pinpoint your AC’s nemesis in no time, ready to vanquish it and reclaim your cool haven.

* Remember: If you’re unsure about any troubleshooting steps, or if the problem persists, always consult a qualified RV technician to ensure safe and effective repairs.

Advanced Alarms: When to Call in the Cavalry

Sometimes, even the bravest adventurers need backup. Frozen coils or clogged drains might make you scratch your head and raise the white flag. Fear not! That’s when you call in the pros, like summoning a squad of AC knights on their trusty service steeds. Remember, attempting major repairs without proper training can be hazardous, so let the experts handle the big guns while you grab a cool drink and admire their handiwork. Here’s a guide for when to seek professional help for RV AC repairs and other major system issues: SunCruiser Media – When to DIY vs Call an RV Tech.

Avoiding Common Blunders: Road-Tripping Without the Drama

Now, let’s equip you with a shield against common AC blunders. First, remember the “Power Play”: respecting your RV’s electrical system like a delicate treasure. We’ll guide you through the differences between RV and residential power, offering cautionary tales that even the bravest knights would heed. Want to conquer the wilderness in comfort? We’ve got your “Boondocking Bliss” toolkit! Learn how to manage AC usage with solar panels, generator know-how, and off-grid tricks to keep your oasis cool even where the power lines don’t roam.

Embracing Humor: The Secret Weapon of RV Warriors

Every RVer’s journey is peppered with quirky AC mishaps. But here’s the secret weapon: laughter! We’ll share hilarious anecdotes and inventive solutions, proving that a sprinkle of humor and a dash of resourcefulness can conquer any unexpected chill-out challenges. Remember, fellow adventurers, the open road may throw shade at your AC sometimes, but with the right knowledge, DIY spirit, and a good dose of laughter, your mobile haven will always be a cool fortress of comfort. So, buckle up, crank up the tunes, and let the frosty adventures begin!

Featured image by Ken Ratcliff via flickr